Printer Types and How to Choose the Right One

Posted by Ben M on Jan 29th 2024

Printers have become indispensable tools for labeling, data collection and organization. For specialized tasks such as printing from digital scales, understanding the intricacies of how these printers work is crucial. This guide explains the workings of several common printer types and provides you with valuable insights on how they work, what functions they can perform and how to choose the right one for your weighing processes.

Printer Types and How They Work

Printers leverage a couple different technologies including thermal printing and dot matrix, also known as impact printing. Thermal printing is a process that involves heat to create clear and precise labels, while dot-matrix printers use ink and pin strikes.

There are two primary methods of thermal printing:

Thermal Transfer Printing

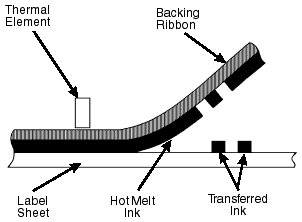

Thermal transfer printing employs a ribbon coated with ink. When heated, the ink is transferred onto the label material, resulting in a more durable print. This method is often preferred for labels requiring longevity and resistance to environmental factors such as chemicals, UV exposure, extreme temperatures and moisture.

As you can see from the image, the ink transferred to the label is heated by the thermal element, or the printing head. Wherever heat is applied, the ink is left on the label. Likewise, areas of the ribbon that don't receive heat results in a blank space on the label.

Thermal transfer printing is one of the most common methods of label printing. Some of the most popular label printer brands include Epson and Zebra. Scales Plus offers a comprehensive selection of printers suited for various label printing applications.

Direct Thermal Printing

Direct thermal printing is a simple yet effective method where heat is applied directly to thermal paper. This causes the paper to darken in specific areas, forming text and graphics. It's a cost-effective solution for applications like shipping labels and short-term product labels and weight and data receipts, such as time, user ID, item ID and more.

Dot Matrix Printing

Dot matrix printers use a print head that moves back and forth on the page and prints by using tiny pins to strike an ink-soaked ribbon against the paper. These operate very similarly to a mechanical typewriter. These types of printers are used in applications where multiple copies of the same weight receipt or weigh ticket are needed.

Choosing the Right Printer

Now that we've identified the types of printers and how they work, let's get into the considerations you'll need to make when selecting the right printer for your application, including compatibility with the scales you are using.

Integration with Weighing Scales

Many scales are designed to integrate with compatible printers. This integration allows the printer to generate labels or tickets based on the weight or information entered into the connected scale. Not all scales are created equal though. Some have the printer built right into the scale itself. Others require additional hardware for connecting the printer to the scale. Typically, they require configuration of the communication port and print formatting. Many scales are able to integrate with simple receipt type printers but might not be able to integrate with a label printer. This is because label printers require more complex control commands to print a label properly.

Contact Scales Plus for printer integration and configuration services.

Compatibility is Key

Before making any decisions, it's crucial to ensure that the printer is compatible with your existing digital scale. Check for compatibility features and, if possible, opt for a printer that offers seamless integration with your current setup. This compatibility ensures a smooth flow of information between devices, preventing any hiccups in your printing process. Some of the key features to look for are communication type, cables and connectors/adapters required, and weigh ticket/receipt vs weigh label formatting options. Many scales are compatible with receipt type printers but often times they do not have the ability to print labels as printing labels typically requires special formatting/program codes.

Print Quality Matters

The quality of your prints is paramount, especially when dealing with intricate product details, barcodes, or pricing information. Consider the print resolution of the printer; higher resolution ensures that your labels are clear, legible, and professional-looking. Pay attention to the printer's capabilities in reproducing graphics and text accurately. This is especially important as it relates to label printing.

Speeding Things Up

In a fast-paced business environment, printing speed is a crucial factor to consider. Evaluate the printer's print speed to gauge its efficiency. This will usually be specified in terms of inches/millimeters per second or lines per second. Faster printing not only boosts productivity but also reduces waiting times in retail or industrial settings.

Labels and Weigh Ticket Creation

The most important thing to consider when choosing a label printer is determining the information needed on the weigh ticket or label and the required format of the data. This information could be your company name, time, date, weight information, product details, etc. Once this information and format has been determined, the scale and printer will need to be programmed for both the data and formatting required. The scale and printer will also need to be configured to communicate with each other properly. Once programming and configuration is complete, the printing can begin.

Connectivity Options

Versatility in connectivity is a key aspect when choosing a scale printer. Look for printers that offer multiple connectivity options, such as RS232 serial, USB, Ethernet, or Bluetooth. This flexibility allows you to connect the printer to a variety of devices, catering to different workflow requirements. Although RS232 serial communication has been around for many years, it is still one of the most common modes of communication used between scales and scale printers.

User-Friendly Interface

A scale and scale printer with a user-friendly interface and comprehensive manual is a time-saving and frustration-reducing asset. Consider the controls, menu navigation, and overall ease of use. Intuitive design and straightforward operation can make a significant difference in the learning curve for you and your team. This may come in the way of printers that include software, out-of-box compatibility with scales, or scales that include an integrated printer. These things help to take the guesswork out of setting up a printer within your processes.

Maintenance and Consumables

Most printers require maintenance and replacement of wearable items such as printing heads, cutters and spools. Make sure replacement parts are readily available or choose a printer that is economical enough to be replaced if maintenance isn't an option. Also consider the environment in which the printer will be used. A robust printer is more likely to withstand the demands of a busy environment, reducing the chances of downtime. Some ticket printers, like those used for ticket systems in truck weighing applications, have a weather-resistant housing that allows them to withstand weather such as rain, ice and snow.

Consumable items such as printer paper, label rolls and ink ribbons should be readily available and easy to order. Make sure you investigate pricing and availability of all consumable items before ordering your next printer.

Practical Applications

Retail

In retail settings, scale printers play a crucial role in generating price labels, barcodes, and product information. The integration with weighing scales streamlines the labeling process, ensuring accuracy in pricing and inventory management.

Industrial and Manufacturing

In manufacturing settings, scale printers are used for labeling products and packages with essential information such as part numbers, part count, package weight, company name, date and time, etc. The durability of prints becomes paramount in these environments where labels may be subjected to various conditions.

Logistics and Shipping

For businesses involved in logistics and shipping, printers are indispensable for creating shipping labels with accurate information. Labels must also include the appropriate data required by carriers such as names, addresses, shipping weights and dimensions, as well as barcodes. This is especially important when creating labels that are adhered directly to a package. The efficiency of the printing process directly impacts the speed and accuracy of shipping operations.

Wrapping Up

In conclusion, understanding the mechanics of scale printers and making an informed choice when selecting one is vital for a smooth and efficient printing experience. Whether you're operating in a retail, industrial, or logistics environment, the right printer for your scale can streamline processes, enhance productivity, and contribute to the overall success of your operations.

Scales Plus offers a comprehensive selection of label and receipt printers for scales from a variety of manufacturers. Most of the printers we offer are directly compatible with popular industrial scales and laboratory balances, requiring minimal setup and configuraton. We also offer more robust label printing options that require additional formatting for more demanding printing needs.

If you need any assistance determining if a scale printer is compatible with a scale or if you need a custom label format, please contact Scales Plus for assistance.