What are Weigh Modules and How Do They Work?

Posted by Jon M on Sep 15th 2023

Weighing accurately might seem like a simple task, but it's a crucial aspect of various industries, from manufacturing to aggregates, as well as custom weighing applications for many others. Enter weigh modules, some of the most versatile systems for precision weighing. In this blog, we'll provide an overview about weigh modules, exploring what they are, how they work, and the vital roles they play in ensuring accuracy and efficiency.

What Are Weigh Modules?

Weigh modules, also referred to as weight sensors, are a system which consists of a combination of load cells and mounting components used to convert the weight or force applied to them into a measurable electrical signal. These modules come in various styles, sizes, capacities and materials, making them adaptable for a wide range of applications.

How Do Weigh Modules Work?

Weigh modules are composed of load cells, mounts and mounting hardware. Load cells are designed to deform slightly when subjected to a force or weight. This deformation generates an electrical signal proportional to the applied load. This signal is then processed and converted into a digital readout by a digital indicator or display, which can be read by the operator.

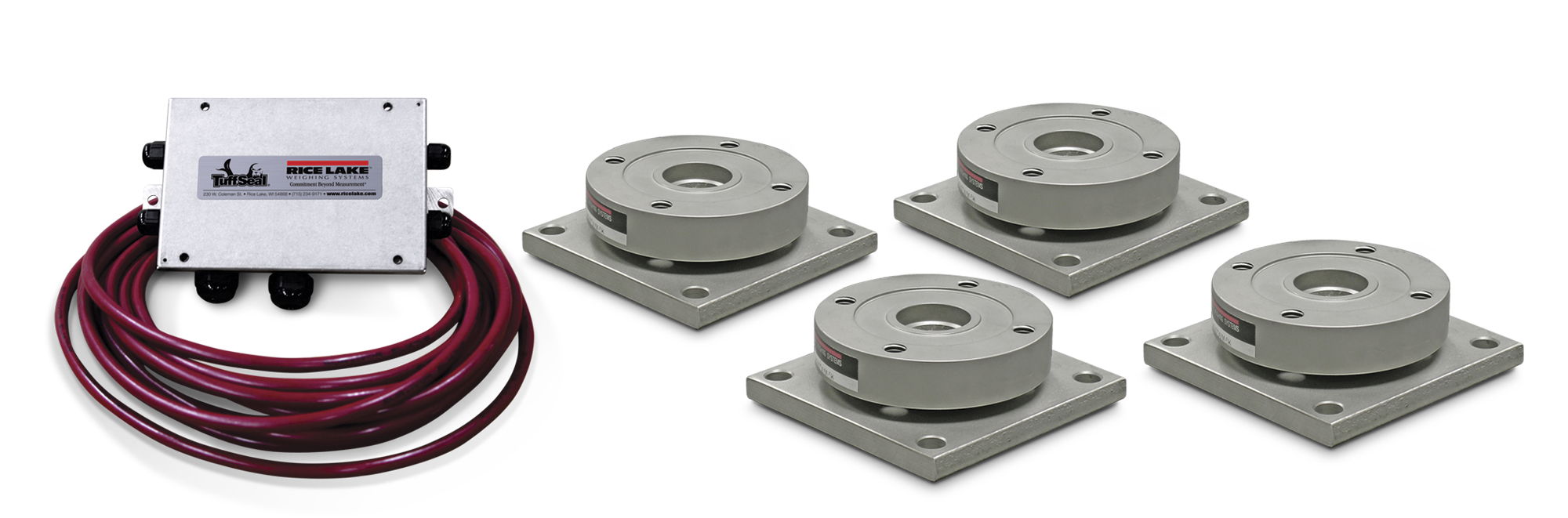

Single-cell and multi-cell weigh module kits include the load cells, mounting hardware and a junction box. The load cells are all connected to the junction box, which takes a sum of all of the individual cells readings and sends a signal to the indicator which displays a single total weight.

Further Reading: What are Load Cells and How do They Work?

Types of Weigh Modules

Single-Cell vs. Multi-Cell Weigh Modules

- Single-Cell Weigh Modules: These modules are ideal for applications requiring precise measurements of relatively small loads. They consist of a single load cell positioned centrally beneath the platform, vessel or apparatus where product is weighed.

- Multi-Cell Weigh Modules: Suitable for larger and more unevenly distributed loads, multi-cell modules use multiple load cells for higher-capacity applications and larger structures.

Compression vs. Tension Weigh Modules

- Compression Weigh Modules: Designed to measure forces pushing down on the load cells, compression modules are commonly used in industrial weighing applications.

- Tension Weigh Modules: These modules are used to measure forces pulling up on load cells, often found in applications like crane scales and suspended hoppers or tanks.

Applications of Weigh Modules

Industrial Manufacturing

Weigh modules are instrumental in industrial manufacturing processes, ensuring the accurate measurement of raw materials, products, and components. They are used in quality control, batch processing, and inventory management.

Food and Beverage Industry

In the food and beverage industry, weigh modules play a crucial role in portion control, packaging, and recipe formulation. Precise measurements are essential to maintain product consistency and comply with regulations.

Logistics and Transportation

Weigh modules are integrated into shipping and logistics operations to determine cargo weights accurately. This ensures safe and efficient transportation and helps prevent overloading. These are commonly found in vehicle weighing systems and high-capacity floor scale systems used for weighing product.

Agriculture

In agriculture, weigh modules are used for livestock weighing, grain handling, and fertilizer distribution. Accurate measurements are vital for optimizing crop yield and animal health. They are often used for tank weighing systems, silos, and conveyor systems.

Aggregate

Weigh modules are very popular in aggregate applications. They are commonly used for hopper, tank and silo systems for mixing and weighing concrete products.

Advantages of Using Weigh Modules

Accuracy and Precision

Weigh modules provide highly accurate and precise measurements, reducing errors and improving product quality. There are a lot of options to choose from with various capacities, configurations and environmental protection ratings to accommodate accuracy requirements of a wide range of applications.

Efficiency and Productivity

Automating the weighing process with weigh modules and suitable indicators saves time and labor. They can be integrated into customized weighing systems and automated weighing processes with unique or restrictive installation requirements. This leads to increased productivity and cost savings in various industries.

Durability and Reliability

Weigh modules are built to withstand harsh environmental conditions and heavy use. They are designed for long-term reliability, ensuring consistent performance over time. Options are available with high IP ratings and stainless steel construction for use in wet environments.

Further Reading: IP Ratings Explained - A Guide for Scale Buyers

Flexibility

The versatility of weigh modules allows them to be integrated into existing systems or customized for specific applications. This adaptability makes them valuable in various industries. Weigh modules can be used to build custom systems like floor scales, hopper scales and tank scales with high capacities. They are particularly useful when weighing non-standard size and shape structures.

The Final Word

Weigh modules are a versatile weight sensors designed to improve accuracy, efficiency, and quality of products and processes across a wide range of industries. From industrial manufacturing to aggregates and agriculture, these devices play a pivotal role in ensuring precise measurements. Understanding the types, applications, and advantages of weigh modules can help you make informed decisions when it comes to incorporating them into your operations. As technology continues to advance, we can expect weigh modules to become even more integral in maintaining the high standards required in today's industries.

Have further questions or need help choosing which weigh modules are right for you? Contact Scales Plus today!