Fun Facts About the Weighing Industry

Jun 20th 2025

When you step onto a bathroom scale or watch a truck roll onto a weighbridge, you’re experiencing centuries of innovation in the weighing industry. From ancient balance beams to today’s million-pound deadweight machines, precision weighing has shaped commerce, science, and daily life. Below are twelve fun facts, each with links for deeper reading.

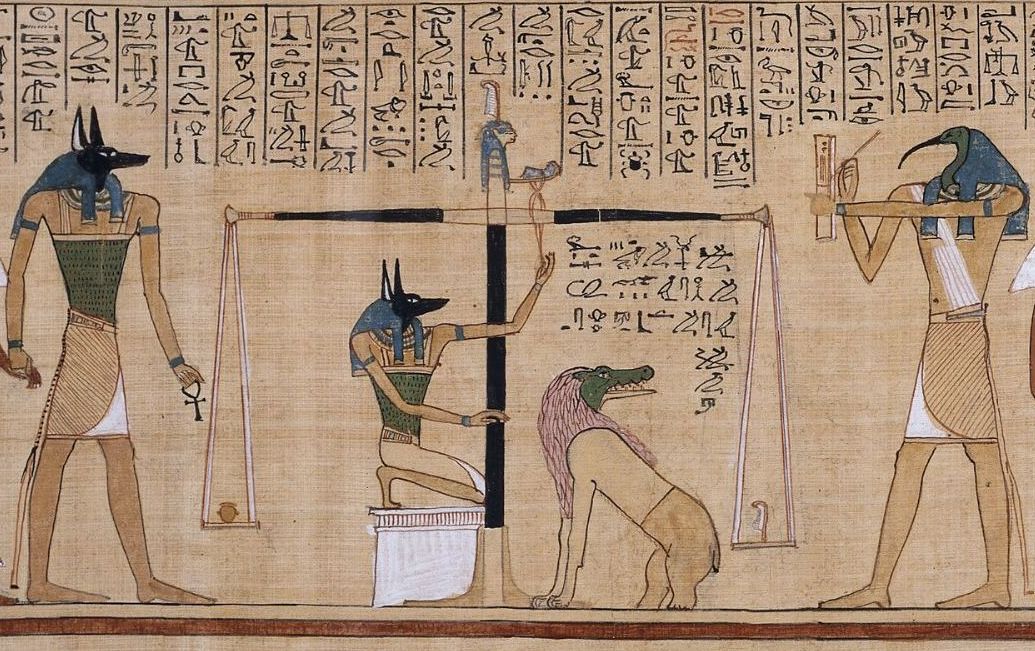

1. Ancient Beginnings: Balance Beams and the “Deben” Unit

Balance beams date back to ancient Egypt (circa 2600 BC). Merchants compared unknown loads against standardized stone “deben” weights to ensure fair trade. Archaeological finds in the Indus Valley (circa 2000 BC) show polished stone cubes used as weights, suggesting parallel developments across civilizations.

2. Medieval to Renaissance Innovations: Steelyards and the Roberval Balance

As trade expanded, merchants adopted the steelyard—a lever-arm balance with a sliding counterweight—to weigh heavy loads with minimal gear. In the 17th century, Gilles Personne de Roberval introduced a parallelogram linkage so both pans stayed level, resulting in the Roberval balance.

Steelyard design · Roberval mechanism

3. Triple Beam Balance: An Affordable Lab Balance

In 1906, Frank Aronson of the Central Scientific Company, invented and patented the first triple beam balance. His goal was to create a laboratory balance that was inexpensive, yet provided reliable measurements. Later, in 1921, Paul Klopsteg joined the company and refined the design. A new patent was issued. Triple beam balances remain a popular weighing solution to this day.

View the Paul Klopsteg triple beam balance "CENCO"

4. Industrial Revolution: Spring Scales and Legal-for-Trade Requirements

The Industrial Revolution spurred demand for portable, low-cost scales. Spring scales measure load by spring deflection (Hooke’s Law) but can vary with gravity and temperature. Modern legal-for-trade spring scales include compensation mechanisms, meeting NIST Handbook 44 standards.

Shop legal-for-trade at Scales Plus

5. Digital Revolution: Strain-Gauge Load Cells and Smart Scales

By the late 20th century, strain-gauge load cells used tiny metal elements whose deformation alters electrical resistance. Amplifiers and microprocessors produce digital readouts. Today’s retail scales print labels, track RFID inventory, and link to POS; industrial weighbridges measure trucks within 0.1 percent accuracy.

How strain-gauge load cells work

6. Ultra-Micro Precision: Nanogram-Level Weighing

Researchers push sensitivity to weigh individual particles. In 2015, University of Tsukuba scientists used micro-cantilevers to measure nanogram-scale masses in liquids, revolutionizing drug discovery and biotech. Commercial lab balances achieve 0.1 mg readability for pharmaceutical analysis.

Read about nanogram-precision cantilevers

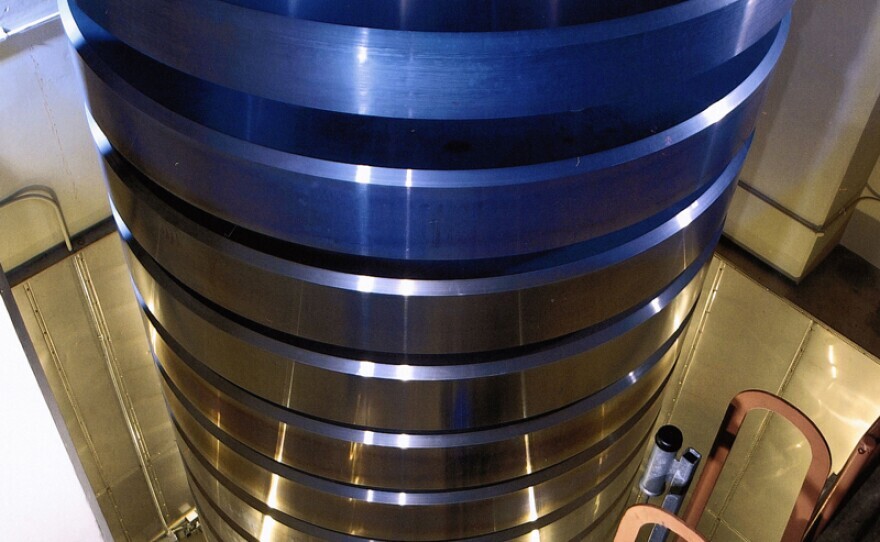

7. The World’s Largest Deadweight Machine: 4.45 MN of Force

NIST’s 4.45 meganewton (one million pound-force) deadweight force machine stacks nineteen 50,000 lbf steel discs in a three-story frame. Since 1965 (refurbished 2016), it calibrates load cells for rocket thrust and machinery with 0.0005 percent uncertainty.

Explore NIST’s million-pound machine

8. Weighing Beyond Earth: Space and Deep-Sea Applications

In microgravity, oscillating spring-mass systems aboard the ISS track astronauts’ bone-density loss. Deep-sea hydraulic piston gauges weigh samples under high pressure, using load cells traceable to primary standards.

Mass measurement in microgravity

9. The Heaviest Object Ever Weighed: A Guinness World Record

The heaviest object ever successfully weighed is the Revolving Service Structure (RSS) of launch pad 39B at the Kennedy Space Center in Florida. A combination of rigging and hydraulic systems were used to lift the structure onto 21 jacking points, and weighed in at an astounding 2,423 tons, or 5,342,000 pounds.

(Image credit: NASA)

10. Cutting-Edge Healthcare Applications

Precision scales are vital in hospitals and research. Operating theaters use sterile surgical scales for dosing medications by weight. In neonatal care, microbalances measure infant formula and medication with extreme accuracy. Biotech labs use ultra-micro scales for single-cell analysis, enabling breakthroughs in personalized medicine.

See our selection of Analytical Balances

11. Emerging Trends: Hybrid Scales, SAW Sensors, Quantum Weighing

The future includes:

- Hybrid elastica-arm scales for self-calibration

- Surface Acoustic Wave sensors for rugged environments

- Quantum-level measurements aiming to weigh single atoms

- IoT-enabled scales feeding real-time ERP data

12. Why Precision Weighing Matters Today

Accurate weighing underpins fair trade, regulatory compliance, and safety. At Scales Plus, we offer calibration services traceable to national standards, plus support for bench scales, platform scales, weighbridges, and deadweight testers.

Whether you are balancing budgets or heavy loads, precision is at the heart of success. Scales Plus is proud to be your partner in accurate measurement and calibration services tailored to your operations. Ready to elevate your weighing performance? Get in touch today and let's keep your processes perfectly balanced.