What are In-Motion Checkweighers and How do They Work?

Jun 20th 2025

In a world where manufacturing and packaging happen faster than ever, keeping things accurate while maintaining speed is no small task. That’s where in-motion checkweighers come in. These machines are quiet workhorses of production lines, checking the weight of products in real time as they move, without ever needing to stop the flow.

Whether you're packaging snacks, bottling medicine, or assembling retail products, checkweighers help ensure every item is exactly what it’s supposed to be. They support quality control, reduce waste, and keep operations in line with regulatory standards, all without missing a beat.

What is an In-Motion Checkweigher?

In-motion checkweighers are specialized machines that weigh products as they travel on a conveyor belt. This is why they are also commonly referred to as conveyor scales. Unlike a traditional scale that requires stationary weighing, an in-motion checkweigher does the job while the line stays in motion, hence the name. It verifies that each item falls within a preset weight range, and if it doesn't, rejection devices can automate removal of the "bad" item. Without ever stopping the line, each package is accurately weighed.

Think of it like a gatekeeper that checks each package as it passes and quietly filters out anything that’s too heavy, too light, or just not right.

How It Works

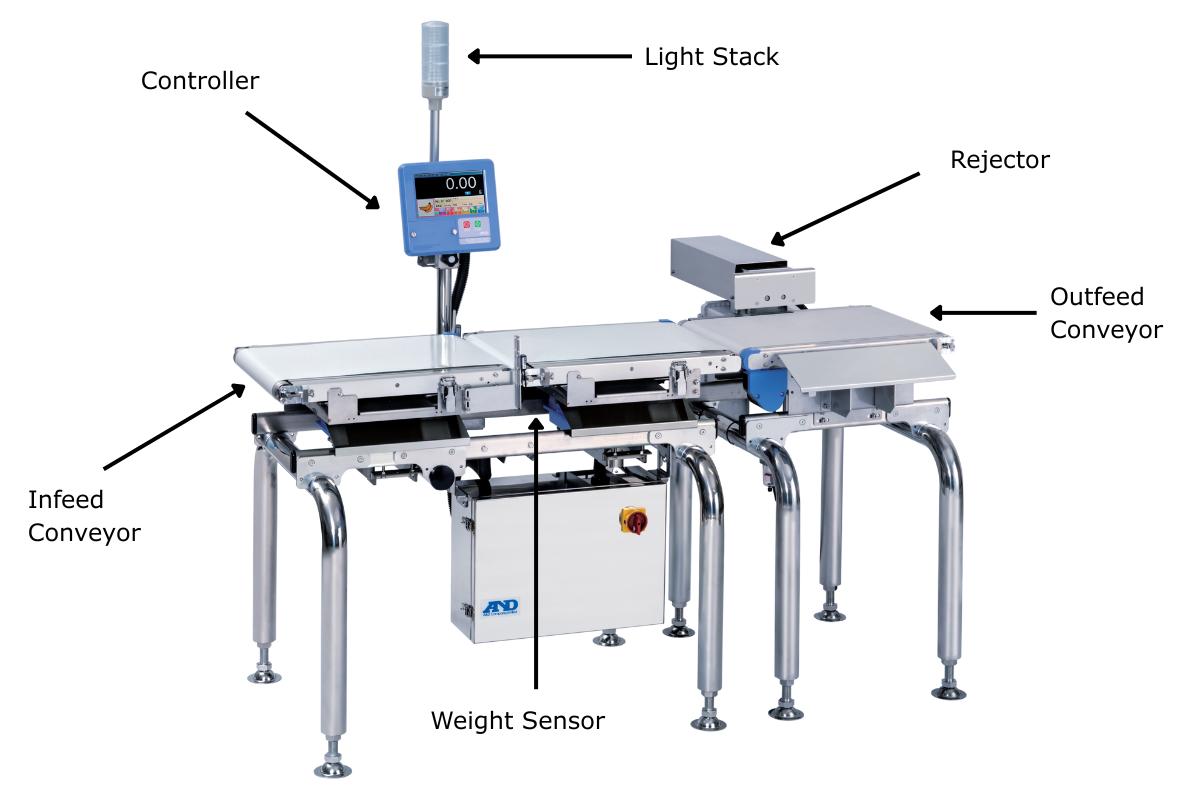

These systems are usually built into a conveyor line and consist of three main parts:

-

-

- Infeed Conveyor: Spaces products out so they don’t bump into each other or interfere with the weighing. The infeed conveyor also ensures a smooth transition onto the weighing conveyor.

- Weighing Conveyor: Uses load cells to measure the item’s weight on the fly. Instrumentation collects the weight, determines if the item is over, under or at an acceptable weight, and handles data management.

- Outfeed Conveyor: Moves items onward and may include a rejection system to remove incorrect ones.

-

As each item crosses the weighing section, the system instantly measures its weight. If the weight is within the acceptable range, the product continues on. If not, it's flagged. What happens next is determined by your process.

Rejection Systems: What Happens to the Bad Ones?

Products that fail the weight check aren’t just ignored, they can be actively removed using one of several types of rejectors. Which one is used depends on the type of product, its weight, and how fragile it is.

-

-

- Full Stop: When a package is under or over the target weight, the checkweigher will stop the conveyor, completely haulting the line. This option is best when a manual process is preferred and an operator can inspect the rejected item.

- Pneumatic Push Rejectors: These use a mechanical arm activated by compressed air to push lightweight or fast-moving items off the belt. They’re quick, efficient, and perfect for snack packs or small boxes.

- Drop-down Rejector: Part of the conveyor simply tilts down and lets the faulty product fall through into a bin. This works well for rigid products that can handle a short drop.

- Air Rejector: A sudden blast of air blows smaller, lightweight items, like pill boxes or pouches, off the line. It’s contact-free and fast.

- Diverter Rejector: A mechanical arm swings out to gently push heavier or more delicate products into a different lane. These are ideal for glass jars, bottles, or anything that could break or spill.

-

How They Work with Automation

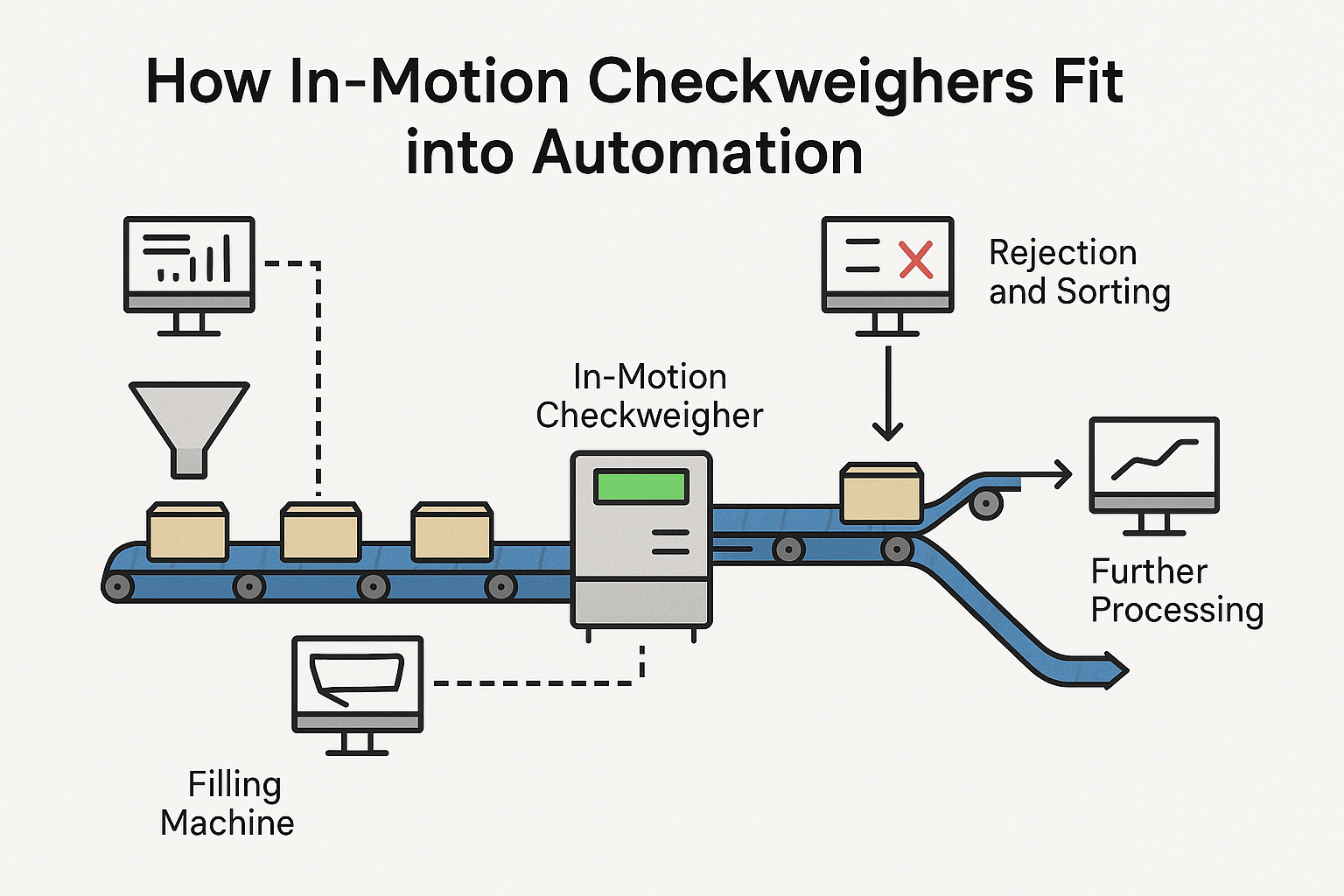

One of the best things about in-motion checkweighers is how easily some of them fit into fully automated systems. They’re not standalone machines, they’re team players. An advanced in-motion checkweighing system includes extensive data collection capability, communication with PLCs, and the ability to activate or de-activate other machines on the same line.

They connect with other machines in the production process like fillers, labelers, and sorters through programmable controllers or factory software. That means they can send and receive information in real time. If something’s going wrong, for example, the filler is adding too much product, they can tell it to make adjustments on the spot.

Here’s what that looks like in practice:

-

-

- Real-time Weight Correction at Filling Stage: If the checkweigher detects a trend, like everything’s coming out 5 grams too heavy, it can send a signal to the filler to make a small adjustment, correcting the issue before it turns into wasted product.

- Automatic Rejection: When an item doesn’t meet the weight requirement, it’s removed automatically. No need for manual checks, which saves time and reduces errors.

- Smooth Product Flow: Because these systems work in real time, they don’t cause bottlenecks or slowdowns. Products keep moving, and the system keeps checking.

- Integration with Factory Control Systems: They communicate directly with central control platforms that oversee the whole production line, helping all machines work together in sync.

- Improved Process Efficiency: By automating the checkweighing process, human error is reduced, and production stays on track with minimal intervention. High speed checkweighers take it a step-further by increasing the speed of product weighing, which means more output.

- Valuable Data Collection: Every weight reading can be recorded. Managers can track this data over time to identify trends, fix problems early, and generate compliance reports if needed.

-

Why It Matters

An in-motion checkweigher's role is much more important than people often realize. These machines touch nearly every product that moves down a line, quietly protecting the process from waste, inconsistency, and costly mistakes.

Here’s why in-motion checkweighers really matter:

-

-

- Ensures Every Item Meets Weight Specifications: Whether you’re selling a bottle of vitamins, a bag of pet food, or a packet of screws, there’s an expectation that the product matches what’s printed on the label. These checkweighers help ensure expectations are met for every single unit, not just random samples. This helps build consumer trust and avoids the risk of legal trouble due to short-weight products.

- Prevent Product Giveaway: Overfilling might seem harmless, it’s just a little extra product, right? But over time, those small giveaways can add up to huge losses. Imagine adding just one gram too much to every package. Over thousands or millions of units, that turns into tons of wasted product. Conveyor checkweighers help companies hit the target precisely, which protects profits without compromising quality.

- Avoid Underfilled Packages: On the flip side, underfilling is a quick way to lose customer confidence or face penalties. If someone opens a box and finds it doesn’t contain what was promised, that’s a problem. Depending on the industry, it could also be illegal. In-motion checkweighers act as a line of defense to catch underfilled packages before they ever leave the building.

- Support Regulatory Compliance: Many industries, like food, pharmaceuticals, and chemicals, are heavily regulated. Companies need to show they’re meeting specific standards, including weight accuracy. Checkweighers can automatically log data for every unit that passes through. This recordkeeping makes audits and inspections smoother and proves that the company is staying compliant without needing piles of paperwork.

- Reduce Waste and Rework: If something goes wrong on the line, for example, a filler starts drifting out of calibration, a checkweigher can catch it almost immediately. That early warning means the problem can be fixed before too many defective products are produced. Without it, you might end up reworking an entire batch or throwing it out altogether, both of which waste time and money.

- Integration with Automated Workflows: One of the biggest advantages of modern conveyor checkweighers is how well they fit into larger automated systems. They don’t just operate in isolation, they talk to other machines. That means they can send real-time feedback to a filler, trigger alarms, sort items automatically, or help adjust the pace of the line. Instead of slowing things down, they actually help keep everything moving smoothly.

-

Where They’re Used

In-motion checkweighers are used extensively in industrial applications. These machines work behind the scenes in dozens of industries, helping to make sure that every package, bottle, box, or product is the right weight before it leaves the production floor.

Let’s take a walk through some of the places they appear and the roles they play in keeping things on track.

Food and Beverage Lines

Food manufacturers rely on speed and precision. Picture a line moving hundreds of granola bars or juice bottles per minute. There’s no time to stop and weigh each one manually, but you also can’t afford to overfill every package or risk sending out one that’s underweight. That’s where in-motion checkweighers steps in.

It checks each product for accurate weight as it moves down the line, flagging anything that’s too light or too heavy. This helps companies avoid giving away too much product, and it protects them from getting fined for short-weight packages. Whether it’s snacks, frozen meals, or bottled drinks, the machine helps ensure every item meets expectations.

Pharmaceutical Packaging

In pharmaceuticals, precision isn’t just nice to have, it’s critical. Imagine a bottle of pills that’s missing one dose, or a powdered supplement that doesn’t contain the full amount. These aren’t small problems. They can impact health, safety, and even legal compliance.

Checkweighers are used to make sure every package contains exactly what it’s supposed to. They’re often part of a larger inspection system, and they help keep manufacturers in line with strict rules and standards. Plus, they gather data that’s used to track batches, spot issues, and prepare for audits.

Warehouses and Shipping Centers

In distribution centers and fulfillment warehouses, conveyor checkweighers play a different kind of role. Here, the goal is to confirm that outgoing packages match what the system expects. If an order should weigh three pounds but only comes in at two, something might be missing.

By flagging these mismatches, they help prevent shipping errors, avoid returns, and reduce customer complaints. For companies that handle thousands of orders a day, that kind of accuracy adds up fast.

Industrial and Chemical Manufacturing

Not all products are delicate or neatly packaged. In industries that deal with chemicals, adhesives, powders, or bulk liquids, weight still matters. A bucket of industrial cleaner or a sack of cement has to meet certain specs, not just for quality, but for safety.

In-motion checkweighers in these settings are often built tough, designed to handle heavier loads and challenging environments. They’re used to verify fill levels and ensure that material contents are consistent from batch to batch.

Agriculture and Feed

On farms and in grain or feed processing plants, weight accuracy plays a role in both fairness and logistics. A bag of seed, for example, has to contain what the label promises. And when you’re stacking pallets for shipping, knowing the correct weight helps avoid load issues and damaged goods.

Checkweighers here are often part of a bagging system, checking each sack or tote as it comes off the line. If anything’s off, it’s diverted for rework or flagged for inspection.

Pictured Above: Scales Plus heavy-capacity in-motion checkweigher

Final Thought

In-motion checkweighers are the quiet guardians of the modern production line. They don’t just improve production, they protect your bottom line, your brand reputation, and your workflow. Whether you're shipping 1,000 bottles a day or 100,000 snack packs an hour, having one of these systems in place means peace of mind with every product that rolls off the line.

Need help finding the right checkweighing solution for your operations? Contact the experts at Scales Plus.